In an Australian first, Wyong company iQ Renew is one in a group of companies which have collaborated to produce a soft plastic food wrapper made from recycled content.

Between them, iQ Renew, Nestle, CurbCycle, Licella, Viva Energy Australia, LyondellBasell, REDcycle, Taghleef Industries and Amcor brought their individual expertise together to collect and process waste soft plastic, turn it back into oil and create a prototype KitKat wrapper.

Food grade recycled soft plastic packaging is a key missing link in Australia’s bid to improve waste management and build a circular economy, with a lack of both collection and processing infrastructure making it difficult to keep waste out of landfill and impossible to meet demands for packaging with recycled content.

Turning soft plastic back into oil is the only path that plastic waste can take if it is to be transformed into a food safe wrapper which is an innovative Australian technology that is ready for commercial roll out.

The initiative emerged from a trial underway by Central Coast Council whereby Wyong recycler iQ Renew and Nestle are working together on kerbside collection of soft plastics.

These collected plastics, together with plastics collected via the REDcycle supermarket soft plastic collection, formed the starting point for the project.

Nestle Australia CEO, Sandra Martinez, said the project had been driven by a shared determination to resolve the soft plastics challenge and an enormous amount of goodwill.

“Between us, we have shown that there’s a pathway to solve the soft plastics problem,” she said.

“To build this at scale, across all states and territories, across hundreds of councils, is going to take a huge effort from government at all levels, from industry and from consumers, but I think it can be done.

“Manufacturers like Nestle will have a key role in driving demand for food grade recycled soft plastic packaging, and creating market conditions that will ensure that all stakeholders throughout the value chain view soft plastics as a resource and not waste,” Martinez said.

To date, soft plastics collected in Australia have been made into products like outdoor furniture, added to road base or used in waste to energy.

CEO of iQ Renew, Danial Gallagher, said that to improve the recycling rate of soft plastics, kerbside collection was an important point of convenience.

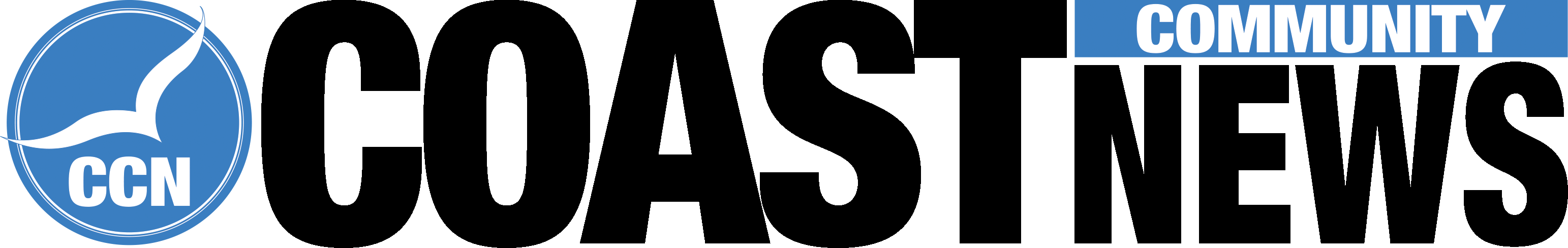

“In the trial, soft plastics are collected from kerbside recycling bins in a dedicated bright yellow bag, then sorted from the recycling stream at our materials recycling facility in Wyong.

“To create the KitKat wrapper with 30 percent recycled content, the soft plastics were processed, then sent to Licella for conversion back into oil using advanced recycling technology.

“This oil was then used to produce new food grade soft plastics,” Gallagher said.

CEO of the Australian Food and Grocery Council (AFGC), Tanya Barden, said learnings from the Central Coast trial will be informative as the AFGC works to develop an extended producer responsibility scheme for hard to recycle plastics, such as soft plastic packaging.

“Among other things, we’ll be looking at how this model can be scaled up, ensuring that there is healthy demand for packaging with recycled content and helping bring to life local industries that can unlock billions of dollars of value that’s currently lost to landfill,” Barden said.

In March, Nestle hosted leaders from across the plastic packaging value chain for a roundtable event, The Wrap on Soft Plastics, exploring the opportunities and hurdles for soft plastics recycling.

“At the event, we shared the lessons learned so far from the Central Coast trial and we will begin to unpack the next steps on the road to reducing soft plastic waste,” said Nestle CEO, Sandra Martinez.

Sue Murray